The bungalow was purchased in 2020. It was built in 1969. It has 2-bedrooms and a rear conservatory. There is a detached garage and a detached lobby which incorporates a cloakroom. It had double glazing throughout. A combination gas boiler supplied the on-demand hot water and the heating via 9 radiators. There was also a backup gas fire in the lounge. The EPC dated August 2019 rated the property in Band D with an energy score of 60.

A series of modifications have subsequently made the bungalow more energy sustainable, including solar panels and an air-source heat pump. The rear view of the bungalow shows the added heat pump. The gas supply was then removed leaving electricity as the only purchased energy supply. There is now no standing gas tariff to pay. An updated EPC has not been issued since the modifications.

Solar Panels, Battery Storage and EV Charger

Installed in 2020 by Advanced Renewable Power of Gateshead. Very good service from ARP although they are now prioritising larger scale commercial installations.

14 Sunpower 320Watt panels were installed on a NSW direction roof providing a total of 4.48kW. ARP installed a Solax inverter and a Solax 5.8kWh storage battery in the roof space. ARP also installed a myenergi Zappi type of 7kW charge point in the garage. This is a smart charger with the option of charging direct from mains or priority charging from the battery. After 2 year’s experience with an electric car I decided to add a second 5.8kWh battery to bring battery storage up to 11.6kWh. For local trips the panels and battery supply the majority of the charging, particularly in the summer half of the year.

Air Source Heat Pump System

Installed in 2022 by Collectvie Green Energy (Yorkshire) Ltd of Thirsk.

Before starting the installation, the roof insulation was supplemented up to 300mm to reduce the overall heat loss.

CGE’s installation comprised:-

- 8.5kW Mitsubishi Ecodan Air Source Heat Pump located outside the lobby/cloakroom:

- 180litre storage cylinder for supplying hot water at a nominal 50°C.

The main initial decision to make was how to integrate the System with the existing pipework of the hot water system and the radiators and where in particular to locate the hot water storage cylinder. This is where different suppliers have different ideas that are not always sensible. The customer’s input is vital.

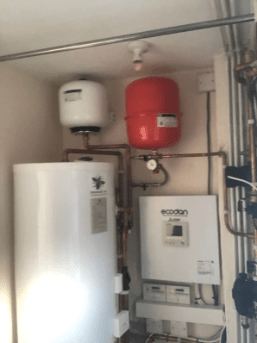

In the case of the bungalow all the existing pipework converged on the gas boiler which was located in the cloakroom of the attached lobby extension. The hot water cylinder was therefore installed in the cloakroom so that that the pipes that were originally plumbed to the gas boiler could be replumbed to connections on the cylinder. Although the cylinder is about 6feet tall and occupies a significant amount of the cloakroom space there was still adequate space for the toilet and wash basin. The residual heat from exposed hot water pipes enables the cloakroom to function as an airing space.

The Mitsubishi Ecodan control panel is located at the side of the cylinder in the cloakroom This enables the temperature settings and program timings to be changed and includes raising the hot water to 60°C every 2 weeks to prevent the formation of legionella bacteria. The heating of the water cylinder by the heat pump can if necessary be supplemented by an immersion heater.

The water circulating through the radiators at 50°C is significantly lower than that from a gas boiler which is typically around 70°C; thus the existing radiators are less efficient at transferring heat to the rooms. Seven of the radiators were therefore changed to more efficient radiator designs. The heating regimes are quite different. The heat pump is usually on continuously; Mitsubishi have shown this is more efficient than switching on and off, as with a gas boiler. This regime produces a more gentle heat with less convection drafts than is experienced with higher temperature radiators.

Inside the house one is rarely aware of any noise from the heat pump. Outside the house the heat pump produces a low hum. The large propeller on the pump produces a gentle breeze that is cooled by the inverse refridgerative effect of the heat pump.

Efficiency of heat pump.

The efficiency can be judged by comparing the energy used by gas with the electricity energy used by the heat pump over successive twelve month periods.

From 1st August 2021 to 31st July 2022 gas used 14625kWh including the electricity used by the boiler.

From 1st August 2022 to 31st July 2023, the heat pump and immersion heater used 3226kWh.

Ratio gas boiler energy / heat pump energy = 4.53:1

This is a very High Ratio compared with literature which rarely shows a ratio above 4.0